Virtual simulation and 3D modeling assure high performance of projects

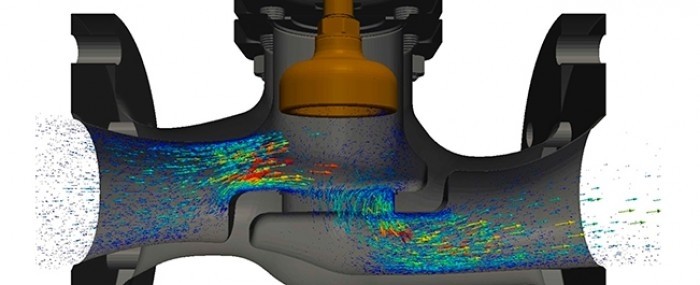

14 de agosto de 2018By Claudia Izique | FAPESP Research for Innovation – Tau Flow, a computational engineering startup based in Campinas, São Paulo State, Brazil, offers the market customized mathematical solutions for the optimization of project performance. It uses 3D computational fluid dynamics (CFD) to develop “virtual prototypes” of any process or environment that involves flows of liquids or gases (defined in physics as fluids).

“Our prototyping solutions use data such as fluid velocity, pressure, temperature, concentration and turbulence. All these data are analyzed by means of mathematical models based on the principle of the conservation of mass, energy and momentum in space-time,” says Marcílio José Caetano, one of the firm’s partners.

CFD and virtual prototyping replace conventional engineering methods and the old technique of “trial and error”, which consumes time and money. “We do simulations,” Caetano explains. “The process is fed into a 3D model, and we identify flaws using mathematical calculations. We then offer a solution that saves time and money, improving the client’s profitability.”

Makers of Formula 1 race cars, for example, use CFD to improve aerodynamics and boost performance while reducing fuel consumption and cost. “In Brazil, however, many firms can’t afford CFD because it’s expensive in itself and requires a highly trained workforce, so we began with the idea of reducing the cost and expanding the market for CFD,” Caetano says.

Tau Flow has clients in the cosmetics industry, in petrochemicals, in metalworking and machine tools, in logistics, and in food. It recently used its technology to evaluate a warehouse complex installation project for Amazon in Cajamar, São Paulo State, and to assess plant performance for mining equipment manufacturer Haver & Boecker in Canada.

“We pursue the ‘milliseconds’ clients need to operate as high-performance players in their market segment. We seek to understand, diagnose, create scenarios and develop solutions for process and project optimization,” Caetano says.

Mathematics of animal breeding

Tau Flow was founded in late 2015 by an electrical engineer, a civil engineer and a chemical engineer at INCAMP, the University of Campinas’s incubator for tech startups. The partners developed a methodology based on CFD software but also had plans to create a tool to collect the data to be prototyped. That same year, they applied to the FAPESP Innovative Research in Small Business Program (PIPE) for funding for a project involving thermodynamic analysis to boost productivity in animal breeding facilities.

The idea was to produce a kit containing not only CFD software but also a multichannel anemometer (an instrument used to measure the speed of fluids) with the capacity to collect air speed and temperature data. Computational numerical simulation would be used to analyze the best layout for a breeding facility climate control system, ensuring more efficient air circulation and more precise thermal control, Caetano recalls.

The idea was tested in a PIPE Phase 1 project that was completed in August 2017. While the research was in progress, the project was one of 15 selected for the Leaders in Innovation Fellowships (LIF) training program held in the UK on October 16-27, 2017, under a partnership agreement between FAPESP and the Royal Academy of Engineering within the framework of the Newton Fund, a UK government initiative to foster research and innovation in developing countries.

“The training was extremely useful,” Caetano says. “It gave us a new perception of our own business, a more commercial and less academic vision of what we do, enabling us to improve the structure of our sales process.”

Among other activities, the LIF program provided consulting by Oxford University. “They advised us for three months,” Caetano recalls. “During that period, they mapped out the European, North American and Asian markets for the solution we’d developed with project funding from FAPESP. The same consultants will assist us in our internationalization process.”

Pricing challenge

Even before completing its PIPE Phase 1 project, the firm had two projects selected for the first edition of Mining Lab, an initiative of Nexa (formerly Votorantim Metais). One is a nanotechnology solution to increase the rate of zinc nanoparticle recovery using CFD. The other uses CFD to model and simulate a zinc oxide kiln with the aim of identifying the factors that generate process losses and proposing solutions to enhance energy efficiency.

Tau Flow is currently preparing for the true development stage, in which it will finalize the development of the animal breeding monitoring and management solution recently approved for PIPE Phase 2.

Meanwhile, Caetano and his fellow proprietors remain optimistic about the prospects for marketing their CFD technology. The challenge is pricing the service. “We operate with a fixed price plus a success fee. The risk is borne by Tau Flow, and if implemented, the improvement will increase the client’s profitability, so remuneration by the success fee is appropriate. However, generally speaking, the Brazilian market still distrusts this form of compensation,” he says.

Company: Tau Flow

Site: tauflow.com/en

Address: Rua Bernardo Sayão, 100 - Unicamp, Campinas (SP), CEP 13083-866, Brazil

Tel: +55 (19) 4141-8440

Contact: tauflow.com/en/contact/