Machine traffic control reduces costs in agriculture

27 de fevereiro de 2018By Suzel Tunes | FAPESP Research for Innovation – Reducing the financial and environmental impact of agricultural production by means of geoinformation systems is the objective of the Brazilian startup SOMO, short for spatial optimization of mechanized operations.

Located in EsalqTec, the incubator of the University of São Paulo’s Luiz de Queiroz College of Agriculture (ESALQ-USP) in Piracicaba, Brazil, and with the support of FAPESP’s Innovative Research in Small Business Program (PIPE), SOMO is developing a farm machinery control system called MacPath for the automated planning of traffic involving tractors, harvesters, sprayers and other farm equipment based on logistics, cost, and field surface characteristics.

Researcher Mark Spekken, an agronomist with a master’s degree in geoinformation from Wageningen University in the Netherlands and a PhD in agricultural systems engineering from ESALQ, explains that farm implements have direct and indirect costs associated with their operation in the field, such as non-productive time spent maneuvering (especially on irregular or steep surfaces) and overlapping of agricultural areas that entails waste of inputs such as fertilizer, pesticide and seeds. “The geographic files generated by the software are inserted via a chip or flash drive into the machine’s autopilot, which uses a satellite navigation system,” Spekken says.

Excessive heavy machine traffic in fields can also cause environmental and financial damage: soil compaction reduces water infiltration, lowering yields and increasing the risk of flooding and water erosion.

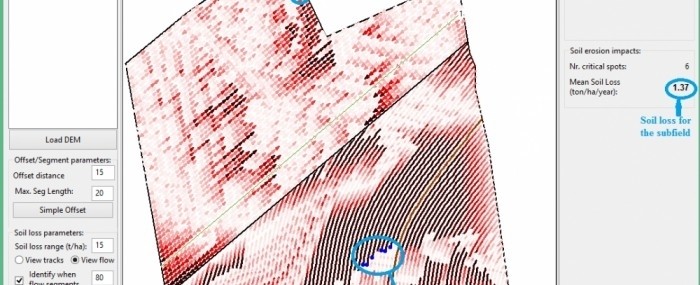

MacPath simulates the possible paths taken when tilling a field in preparation for planting, seeking the optimal route to minimize the impacts mentioned and make the best possible use of the area. “The system uses logistical and environmental cost data [soil types, rainfall frequency and slope gradient, for example] and converts these variables into clear impact information such as cost per hectare or the amount of soil lost to water erosion for each simulation,” Spekken explains.

“MacPath can be compared to a navigation system that seeks the optimal route for a car in a city. Instead of information such as traffic intensity, road conditions and speed limits, the system considers surface relief, rainfall intensity, soil type, and machine drivability.”

According to Spekken, the system will be particularly beneficial for crops – like sugarcane – with significant operating costs, as it enables planting and harvesting to be optimized without harm to the environment. “Compared with traditional traffic planning, it’s possible to predict a 20%-40% reduction in operating costs by means of the system,” he says.

Strategic pause

SOMO conducted Stage 1 of its PIPE project for MacPath between November 2015 and July 2016, achieving the proposed objectives. “A prototype system has already proven highly functional and has even aroused the interest of large companies in the agricultural sector,” Spekken says.

However, before continuing with the project, he concluded that it would be difficult to convert interest in the innovation into a concrete change of attitude on the part of farmers who are accustomed to the use of computer-aided design (CAD) platforms.

“These systems neither simulate nor quantify financial and environmental impacts,” he says. “The robustness of planning done by means of CAD software is highly dependent on the user’s intuition and experience, which may result in operational or environmental impairments. MacPath, in contrast, generates several crop establishment orientation scenarios and quantifies the relevant impacts.”

It was the agricultural industry itself that eventually pointed Spekken to a business alternative. Inspired by the popularization of drones, in September 2017, the firm launched another product called Inforow, a software solution that analyzes planting patterns and faults using high-resolution aerial images. According to Spekken, the software identifies planting traffic errors and faults in a field, generating spacing and harvesting lines that can be exported to the harvester’s autopilot to avoid excessive mechanical pressure and soil compaction.

Inforow was designed in-house without any outside assistance in response to immediate market demand, leading SOMO to prioritize the product’s development in the past year, Spekken explains. Its main customers are in the sugarcane segment.

On completion of PIPE Stage 1, the firm therefore “embraced the drone cause”, as he puts it, and opted for a strategic pause in the development of MacPath.

“We view Inforow as a product that’s already inserted in the market. We expect new versions of MacPath, which is in the prototype stage, to also be adopted by the segment in which we already have our main customers. We believe having a product that’s already been adopted by the market will facilitate adoption of MacPath in the near future,” Spekken says.

Company: SOMO

Site: esalqtec.com.br/project/somo

Address: Avenida Limeira, 1131 - Areão - Piracicaba (SP), CEP 13418-900

Tel: +55 19 3421-3500

Contact: esalqtec.comunica@gmail.com