3D bioprinting is used to produce cellular structures

05 de novembro de 2019By Eduardo Geraque | FAPESP Innovative R&D – A technological platform developed in Brazil with the potential to revolutionize tissue engineering is the basis for 3D Biotechnology Solutions to grow its business. Known as 3DBS, the startup is headquartered in Campinas, São Paulo State.

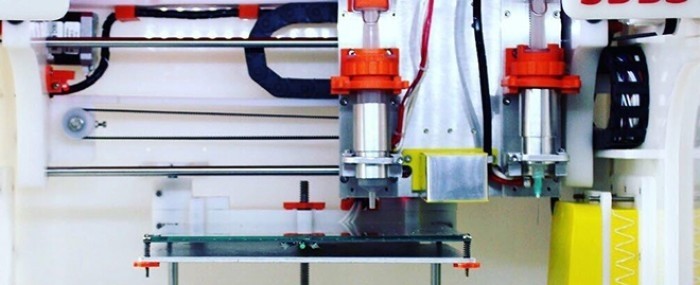

With funding from FAPESP via its Innovative Research in Small Business program (PIPE), 3DBS developed a project to customize 3D printing technology for the production of three-dimensional cellular structures. It completed the project in early 2019.

The firm then began producing commercially, and a dozen of its bioprinters are now up and running. They are all being used by research groups for educational purposes or applications in the area of tissue engineering and regenerative medicine.

“Every customer has unique needs, so our product customization and specialized technical assistance are important,” says biologist Ana Luiza Millas, one of the startup’s partners.

Unlike conventional 3D printers, which can operate in any environment, the bioprinters used to mimic living tissue use cellular material and must be installed in cleanrooms, running inside flow chambers with air control.

According to Millas, the bioprinting of skin, cartilage and bone uses bioink, a live cell-laden fluid in a biopolymer gel developed specifically for this application. “The technique mimics live tissue, a huge challenge. Imitating nature’s perfection and complexity is no easy task,” she says. “The current sticking point is how best to combine different kinds of cells with materials that resemble the native matrix of human tissue, and how to keep the printed structures alive and functional for days, months or even years.”

The combination of artificial matrices with specific cell material in large-scale printing opens up a broader range of possibilities for tissue engineering. In this multidisciplinary and interdisciplinary field, one of the main aims of the hundreds of research groups that are experimenting with bioprinting in Brazil and elsewhere is to create live biological materials with which to partially or totally enhance or replace tissues or organs damaged by disease or injury.

Bioprinting of a functional heart or liver in a cleanroom of a laboratory anywhere in the world is still far in the future, but there are other less remote possibilities. “One of our next steps will be to collaborate in the market for in vitro skin models that can be used by the pharmaceutical and cosmetics industries,” Millas says.

Another potential avenue for the development of the technology is regenerative medicine, including the bioprinting of novel wound dressings to treat burns or severe skin lesions, for example.

The firm also plans to use the technology to test medical drugs and beauty products now that Brazil has banned animal testing by the cosmetics industry. A normative resolution by the National Council for Control of Experiments with Animals (CONCEA) instituted the ban on September 24.

Company: 3D Biotechnology Solutions

Site: www.3dbiotechnologiessolutions.com/en/home/

Contact: www.3dbiotechnologiessolutions.com/en/contact-us/